October 2004

The month for filleting.Devlin's lightbulb in a box idea to warm the resins works a treat. I've also bought some ±45° 150mm wide tape for the fillet reinforcement. The 0/90° I've been using up to now is probably fine but technically a poor substitute.

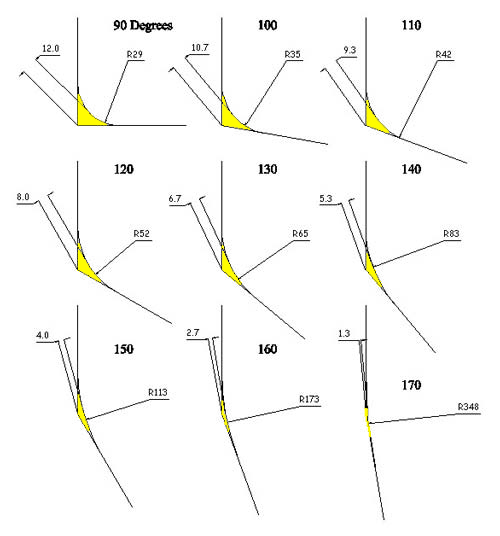

Devlin recommends that the fillet thickness be at least equal to the thickness of

the thickest panel to be joined. But there is no mention of the influence of the

included angle between the two panels. Clearly it can't apply when the panels butt

at 180°. If I allow the fillet thickness to decrease linearly with panel angle

I produce this family of fillet radii. Interestingly they produce roughly equivalent

fillet widths as well.

Or Graphically

Which is all very well until you examine the variation of included panel angle

along the hull.

So for the fillets with the greatest angle change over their length I made an

involute fillet template. You need to mark the fillet width on both panels otherwise

you don't know which bit of the template to use. As you slide along the fillet you

rotate the template to change the fillet radius and hence maintain the fillet thickness.

It takes a little practice and I suggest you make it from thicker platic than the 1.5mm I used.

So for the fillets with the greatest angle change over their length I made an

involute fillet template. You need to mark the fillet width on both panels otherwise

you don't know which bit of the template to use. As you slide along the fillet you

rotate the template to change the fillet radius and hence maintain the fillet thickness.

It takes a little practice and I suggest you make it from thicker platic than the 1.5mm I used.